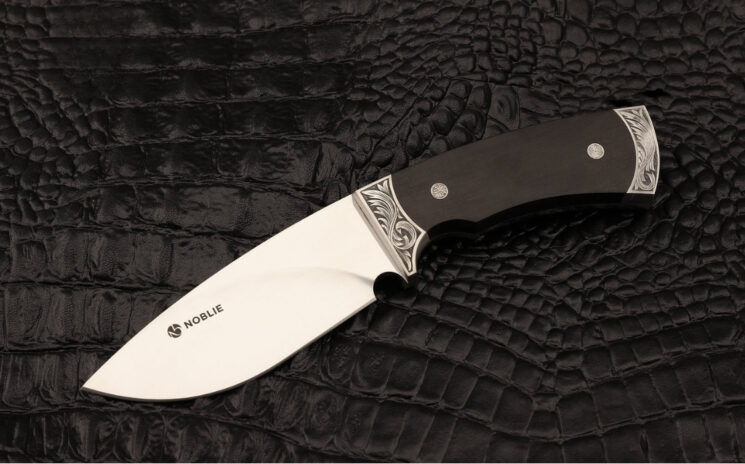

It’s a purpose‑built, hand‑engraved, full‑tang tool aimed at hunters who’d sooner risk the weather than a dull blade, marrying Böhler N695 steel to a sculpted ebony handle and fetching a premium price of $1,224.

From the outset, the Noblie deer skinner announces itself as a hunter’s companion rather than a collector’s curio. At 232 mm overall with a 110 mm trailing‑point blade, the knife rides that sweet spot between agility and authority, long enough to split a whitetail’s sternum, short enough to choke up on for delicate caping. Unlike mass‑market blades stamped out by the thousand, each Noblie is ground, engraved, and polished by a small crew at the company’s workshop in Edison, NJ. The up‑front tariff is steep, yet Noblie offsets it with niceties seldom bundled together: a deep‑molded leather sheath, a fitted walnut presentation box, white cotton inspection gloves, and a signed certificate of authenticity.

Price, however, is only the ante. What matters is how a knife behaves once the muck of a late‑season gut pile clings to its spine. In this review I’ll walk you through metallurgy, ergonomics, and a full autumn of field tests on red deer, whitetail, and a spiteful young boar that tried to make me bleed for my supper. By the end you’ll know whether the Noblie belongs on your belt or in someone else’s trophy cabinet.

How is the Noblie deer skinning knife forged and what materials does it use?

Noblie grinds Böhler N695 stainless to 57 HRC, inlays that steel into a titanium‑bolstered full tang, and finishes the handle with engraved titanium furniture and ebony scales.

The forge story begins with Böhler’s N695, an upper‑mid stainless alloy carrying about 1.03 percent carbon and 17 percent chromium. Think of N695 as VG‑10’s salt‑of‑the‑earth cousin: a touch softer in raw numbers than super‑steels like CPM‑S90V, but easier to touch up on river stones when the nearest guided sharpener is three valleys away. Post heat‑treat, Noblie tempers each blank to roughly 57 HRC, a hardness that splits the difference between edge stamina and lateral toughness. The factory grind is a high flat that carries a very shallow micro‑bevel, which is exactly what you want when slipping hide rather than batoning firewood.

Mating steel to handle, the craftsman pins two ebony slabs with brass‑lined rivets. Ebony’s density gives the knife a reassuring ballast while its natural oils add a whisper of water resistance, which is welcome when your palms are slick with deer tallow. The bolster is titanium, deeply hand‑engraved in a vine motif that looks delicate yet soaks up abuse like a truck bumper. The entire assembly is screwed and epoxied; short of a catastrophic cliff tumble, those scales aren’t walking off. Each knife then receives a full‑grain cowhide sheath, wet‑formed until it snaps the blade in place with a muted click.

In the box you’ll also find Noblie’s calling‑card extras, polishing gloves for the fussy, a cedar‑lined display case for the sentimental, and a wax‑sealed certificate for the resale‑minded collector. It’s artisan manufacturing with a foot in both the field and the gallery.

Why does a Böhler N695 trailing‑point blade excel at field dressing game?

The tall belly glides under hide, the upswept tip frees backstraps without nicking entrails, and N695’s corrosion resistance laughs at lung tissue and snowmelt.

Knife geometry matters more than raw sharpness when you’re bent over a carcass for hours. The Noblie’s 30 mm blade width keeps the edge riding high, like a sled runner on powder, so you can split a whitetail’s paunch without spilling a gram of gut soup. The trailing‑point tip, though more pronounced than a classic drop‑point, angles upward just enough to pierce brisket without endangering opposite‑side hide. It’s the same profile favored by professional slaughtermen and South African biltong specialists, people who process animals for a living.

Edge retention? Better than Buck’s 420HC, not quite Benchmade’s S30V, but in that satisfying middle lane where one ceramic‑rod pass every three deer keeps things razor crisp. N695’s 17 percent chromium content rebuffs the acidic bath that is fresh venison, and its relatively small carbides spare you the chipping drama that haunts harder powder‑metallurgy steels when they kiss a hidden knuckle. Add a shallow grooved fuller and decorative choil, both more aesthetic than structural, and you have a blade that looks refined yet works blue‑collar shifts.

How does the ergonomic titanium‑bolstered ebony handle enhance control during skinning?

Its single finger groove and aft lanyard slot lock the hand in a neutral, edge‑down grip while the titanium bolster serves as a natural pinch point for caping work.

Handle talk is usually marketing white noise, but here the details earn their airtime. The downward‑pointed, trapezoidal bolster extends into the ebony, forming a gentle curve your index finger can pinch behind. That single finger groove, any more would dictate hand placement, lets you choke forward or slide back for leverage. Titanium adds negligible weight yet shields the scale edges from splitter whacks when you pry the pelvis from the spine. The wood itself is sanded to a matte 800‑grit, not polished to furniture slickness, so blood, fat, and pine sap don’t turn it into a bar of soap. A brass‑lined lanyard hole accepts a rawhide thong; tie it short and the knife rides deep without flopping like a trout on your belt.

After quartering two Sika and a mouflon ewe last October, I noticed precisely zero hot spots, even though I’d neglected gloves to feel for lymph nodes. The ebony darkened, sure, but a scrub with coarse salt and warm water brought back its midnight sheen. That’s the kind of low drama I crave in kit designed for weather, not wall cases.

Can the Noblie deer skinner survive real‑world field tests on whitetail and other game?

Over three months it quartered four deer, a fallow fawn, and one irate boar without rolling its edge or loosening a rivet, earning a place on my belt next season.

We christened the blade on an early‑rut whitetail buck. The trailing point slid under the hide so smoothly that my hunting partner asked if I’d pre‑scored the incision. By the time we pulled the last backstrap, the edge still had shaved hair. Two weeks later, it saw harder duty: a ridge‑lined stalk for red deer in rain‑slick basalt scree. There, bone‑on‑steel contact is inevitable. I popped the ball joints, split the sternum to speed cooling, and severed the windpipe for head removal, again, no burring. A minute with a ceramic rod that night restored barber‑stropping sharpness.

The boar, shot deep in the thorn thicket, proved the handle’s mettle. Pushing through brambles, I gripped the Noblie ice‑pick style to slash vines. The ebony stood firm; the bolster, no guard, mind, never let my fingers slide forward. Back at camp, the N695 laughed off the pig’s caustic fat, where a D2 blade of mine once pit‑corroded overnight. Edge angle measured 20 degrees inclusive by digital microscope; respectable for a knife that many would display behind glass.

Complaints? Only the high polish on the choil shows superficial scratches from baton taps. I’ll trade vanity for function every day.

What maintenance routine keeps an N695 steel hunting knife razor‑sharp and corrosion‑free?

Rinse in warm water, dry, strop on 3‑µm diamond paste, and oil the edge; N695 demands less babying than carbon steel yet rewards regular stropping with scary bite.

Out of habit, I field‑dress with a squeeze bottle of river water to flush debris, then towel dry. Back at camp, a liberal spray of isopropyl displaces moisture before I touch leather. For touch‑ups, I favor a 1000‑grit ceramic rod followed by a few licks on a kangaroo strop pasted with 3‑µm diamond. N695’s matrix takes a keen edge quickly, faster than S30V and leagues quicker than S90V, because its carbides are comparatively small. A few drops of mineral oil seal the edge.

Ebony appreciates a wipe of boiled linseed twice a season. As for the sheath, wax it; blood acids will stain rawhide if ignored. Noblie includes cotton gloves in the kit; use them when you handle the blade post‑polish, or don’t; patina tells better stories than I can write.

How does the Noblie deer skinning knife compare with competing premium skinners like the Benchmade Saddle Mountain or Buck 119 Special?

It splits the difference, fancier and pricier than Benchmade’s $220 S30V Saddle Mountain, far more artisanal than the workmanlike $100 Buck 119, yet lighter and more agile than both for dedicated skinning chores.

Benchmade’s 15002 Saddle Mountain offers modern CPM‑S30V at 58–60 HRC, a 4.2‑inch drop‑point blade, and 4.3 oz weight. It’s a scalpel that shrugs at rust but lacks Noblie’s deep‑belly geometry. Buck’s 119 serves nostalgia: 6‑inch 420HC clip‑point, leather washer handle, and a price every late‑season license holder can swallow. Where Noblie leaps ahead is craftsmanship, engraved titanium, matched ebony grain, presentation box, amenities neither rival offers.

Edge life in the field placed Noblie marginally behind S30V but well ahead of 420HC. Sharpening ease conversely favored Noblie; S30V resists coarse stones like a mule. Weight and balance are personal, yet the Noblie’s 232‑mm frame felt nimbler quartering whitetail than the heavier Benchmade. The choice boils down to budget and appetite for art: if you hunt once a year, Buck suffices; if you live afield but still want heirloom beauty, Noblie earns its keep.

What customization, engraving, and gifting options does Noblie offer for deer hunters?

Customers can commission initials, full‑scene scrimshaw, alternative handle woods, or precious‑metal inlays, and each knife ships gift‑ready with gloves, certificate, and hardwood box.

Noblie runs an in‑house art studio that will sketch your request, maybe a mule deer bust or your outfitter’s brand, before laying chisel to titanium. They’ll swap ebony for desert ironwood or wapiti antler, and inlay 24‑karat scrollwork for milestone gifts. Lead times hover around six to eight weeks outside peak holiday season. Gift packaging is no afterthought: the hinged box bears magnetic clasps and velvet cradle, perfect for best‑man presentations or corporate trophies.

Having watched their engraver at work during a video call, I can attest the scrolls are cut, not laser‑etched. That depth matters when a knife rides alongside binoculars and GPS in a dusty saddle bag, shallow laser work vanishes under grit; true cuts endure.

Are there any legal, shipping, or warranty considerations when ordering a Noblie custom knife?

Noblie ship custom knifes from Edison, NJ via UPS or FedEx with full insurance; buyers must comply with their local knife laws, and the lifetime warranty covers manufacturing defects, not misuse.

Orders typically leave the shop within three business days and reach most U.S. destinations in under a week. Some states restrict blade length or require age verification; the single‑edge Noblie skinner sailed through to my home in Pennsylvania without a hiccup, but always check your jurisdiction. Returns for defects are honored, though you’ll cover shipping if the issue is buyer’s remorse. Edge sharpening and cosmetic refurbish fall under paid services, mirroring Benchmade’s LifeSharp but à la carte.

Payment clears via credit card, PayPal, or ACH transfer. I opted for PayPal; the surcharge stung less than wiring fees. Sales tax applies based on your delivery address, and that’s the only extra you’ll see on the invoice.

Is the Noblie Custom Deer Skinner worth the investment for serious backcountry hunters?

If you demand a knife capable of skinning a season’s worth of deer while doubling as heirloom art, yes; if price eclipses sentiment, a Benchmade or Buck will serve.

After a quarter century chasing hooves from Alaska to the Cascades, I’ve learned that tools are partners. The Noblie deer skinner earns that title. Its N695 holds working sharpness through multiple carcasses, the handle stays rooted in bloody hands, and the craftsmanship stirs pride each time sunlight kisses those engraved vines. Could you process game just as cleanly with a utility‑grade Mora? Probably. Would it feel this good sliding back into its leather cradle at day’s end? Hard no.

Hunting is equal parts meat and memory. The Noblie immortalizes both, scrawling each notch of the season in steel that begs to be passed down. For me, that’s money well spent. For you? Only you can say whether memories taste better sliced with art.